1. Why is choosing the right work shoes so important?

Work shoes are one of the key elements of protective equipment. Their task is not only to protect the feet from mechanical injuries, but also to ensure comfort in difficult conditions, such as long working hours, unfavorable weather conditions or dangers related to the environment. Poorly selected shoes can lead to abrasions, calluses and even more serious injuries, such as sprains or fractures. That is why it is so important to consider not only the price, but also the functionality and specificity of the work when choosing work shoes.

2. Types of work shoes

There are various types of work shoes available on the market that meet various safety standards and norms. Depending on the work environment, these shoes may have additional protective elements, such as reinforced toes, puncture-resistant soles or anti-slip properties. Here are the most popular types of work shoes:

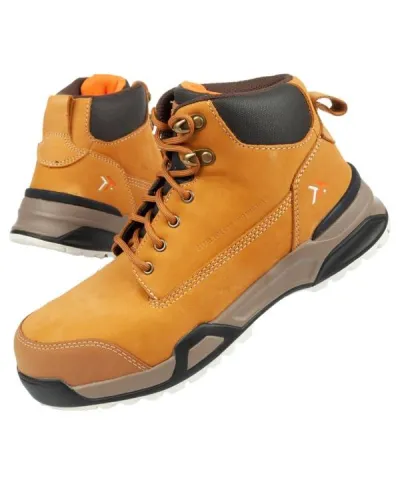

a) Metal toe shoes (S3 safety shoes)

Metal toe work shoes, also known as S3 safety shoes, are one of the most popular models, especially on construction sites and in warehouses. The metal toe provides protection against crushing the toes, which is important when working with heavy materials or in places where there is a risk of objects falling on the feet. Additionally, many of these shoes have non-slip soles and anti-puncture inserts that protect against sharp objects puncturing the sole.

b) Composite toe shoes

For people who need lightweight work shoes but do not want to give up protection, composite toe shoes may be the ideal solution. These types of shoes are lighter than traditional metal toe models, while providing a similar level of protection. Composite toes do not conduct heat or cold, which makes them more comfortable in changing weather conditions.

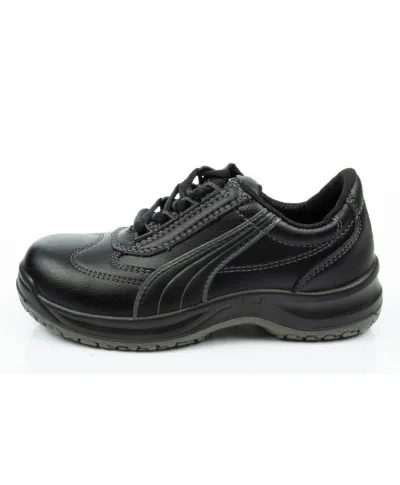

c) Non-slip shoes

In work environments such as kitchens or warehouses, where surfaces can be slippery, non-slip shoes are particularly important. The soles of these shoes are made of materials that provide excellent grip, even on wet or oily surfaces. In kitchens, where spilled water or oil is common, this type of footwear is crucial for the safety of employees.

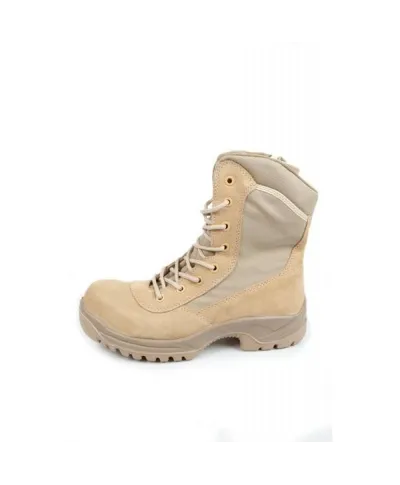

d) Waterproof shoes

Working outdoors, especially in weather conditions such as rain, snow or mud, requires appropriate waterproof footwear. Waterproof shoes are often made of materials that not only protect against water but also provide breathability, which prevents excessive sweating of the feet. For construction workers, surveyors or people working outdoors, waterproof shoes are an absolute must.

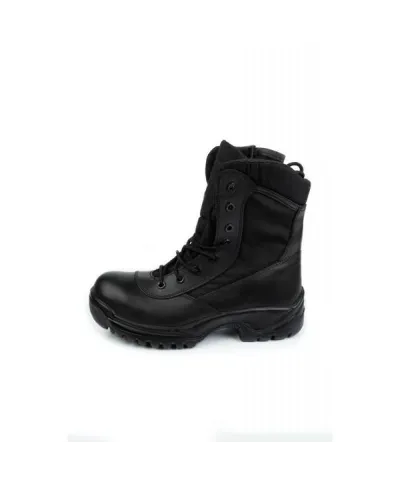

e) Insulated shoes

In winter conditions, when temperatures drop below zero, work shoes must not only protect against injuries, but also provide adequate thermal insulation. Insulated shoes are equipped with special insulating layers that protect against the cold. These shoes are essential for those working outdoors, especially during the winter months.

f) Dielectric shoes

For those working with electrical installations, such as electricians, dielectric shoes are essential. They are designed to protect against electric shock. These shoes are made from non-conductive materials, which reduces the risk of contact with live wires.

3. How to choose work shoes for specific work conditions?

Each industry has its own specific requirements that must be considered when choosing work shoes. Here are some key tips to help you choose the right shoes for different conditions:

a) Construction shoes

Construction is an environment full of hazards. Workers are exposed to heavy objects falling, sharp tools, uneven surfaces and extreme weather conditions. Therefore, construction shoes must meet high safety standards. In this case, safety shoes with a metal toe (S3), non-slip sole and anti-puncture insert will work best. It is good if the shoes are also waterproof, especially when working outdoors.

b) Warehouse shoes

Working in a warehouse often requires walking on even but hard surfaces. Warehouse shoes should provide protection against impacts and crushing, which is why models with a protective toe are a popular choice, but at the same time they must be lightweight and comfortable so as not to strain the feet during long hours of work. An anti-slip sole is also important, because spilled liquids or other contaminants can happen in warehouses.

c) Shoes for working in the field

For employees who spend most of their time in the field, such as surveyors, foresters or road workers, shoes that provide protection against weather conditions and difficult terrain are key. In the field, waterproofness, durability and good grip are key. Insulation will be an additional advantage in the colder months, and reinforced toes will protect against accidental injuries.

d) Kitchen shoes

In catering kitchens, where floors can be slippery and employees are exposed to hot liquids and sharp tools, anti-slip shoes are an absolute must. Additionally, footwear should be made of easy-to-clean materials that are resistant to grease and water. Comfort is also important, because kitchen employees spend long hours on their feet.

e) Driver's shoes

Drivers, especially truck drivers, need shoes that are comfortable for long periods of sitting, but also provide good grip on the pedals. It is important that the shoes are lightweight and flexible, while also having reinforced elements that protect the feet from impacts when loading and unloading goods.

Summary

Choosing the right shoes for work is crucial for safety and comfort in the workplace. Regardless of whether you work on a construction site, in a warehouse, in the field, in the kitchen or behind the wheel, properly selected work shoes can significantly affect the quality and comfort of your work. Remember to pay attention to the specifics of the job performed, as well as the safety standards that the shoes must meet, when choosing shoes. Safety, comfort and functionality should be priorities when buying work shoes.

When choosing construction shoes, warehouse shoes or other work shoes, it is worth investing in proven models that will provide maximum protection and comfort during long hours of work.